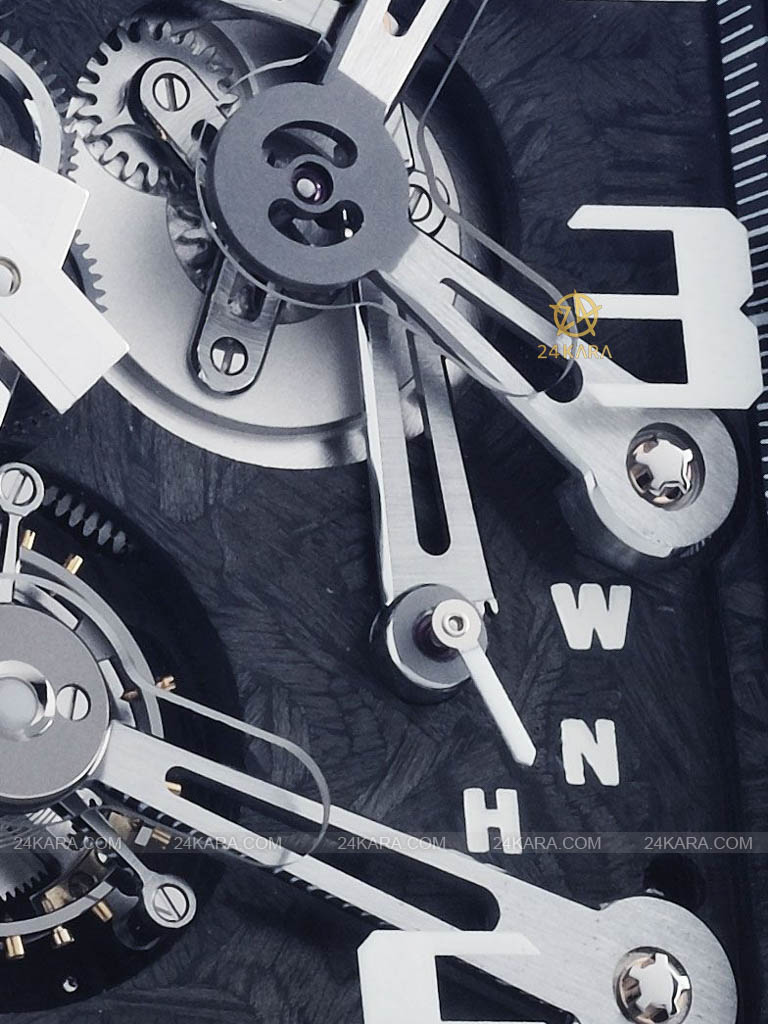

Đồng hồ Richard Mille RM 020 Tourbillon Pocket Watch

Đồng hồ Richard Mille RM 020 Tourbillon Pocket Watch

Bảo hành 5 năm quốc tế

Giá thị trường 15.047.000.000 VND

Giá 9.074.300.000 VND

TIME AND INFINITE SPACE

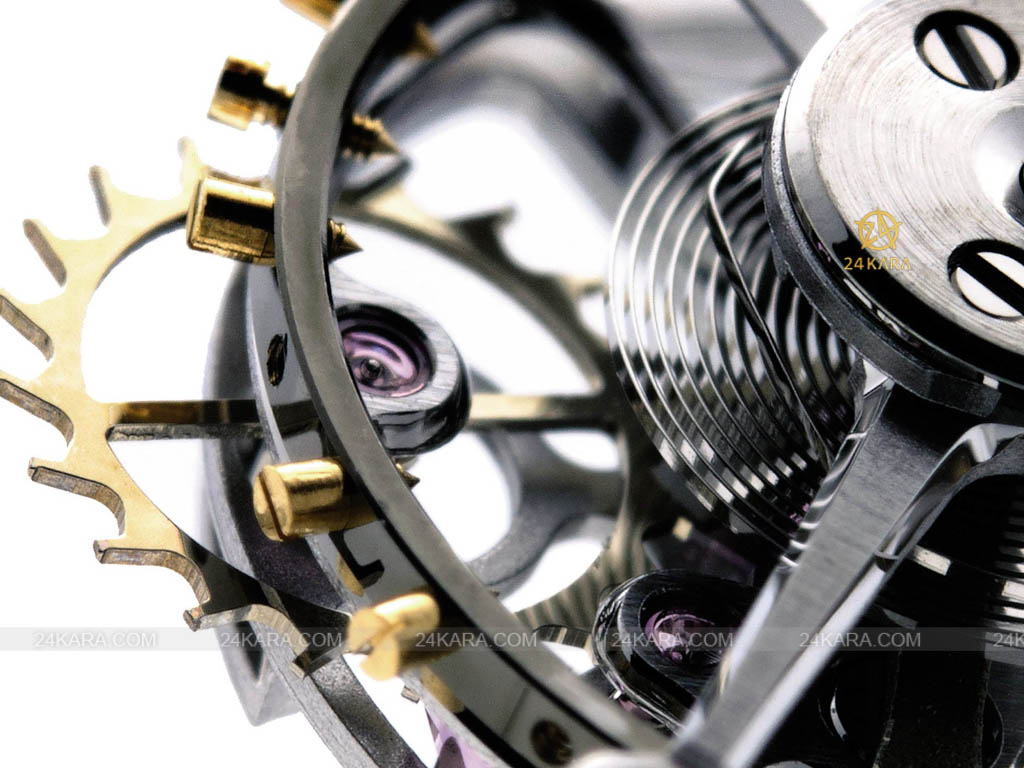

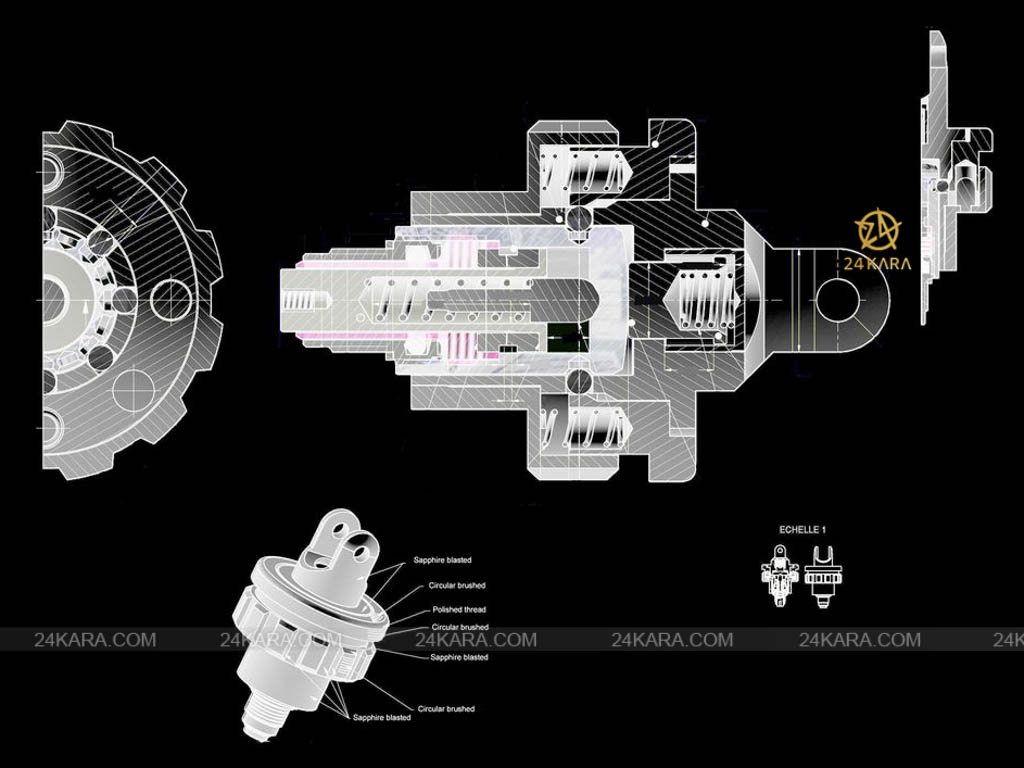

'The first pocket watches were great technical achievements, bringing timekeeping to the world of the private and personal for the very first time in history. It preceded the appearance of the wristwatch by several centuries. With our deeply held aesthetic convictions and experience in mechanical technology, we were keen to revisit and radically modernise the concept behind this archetype for a long time.

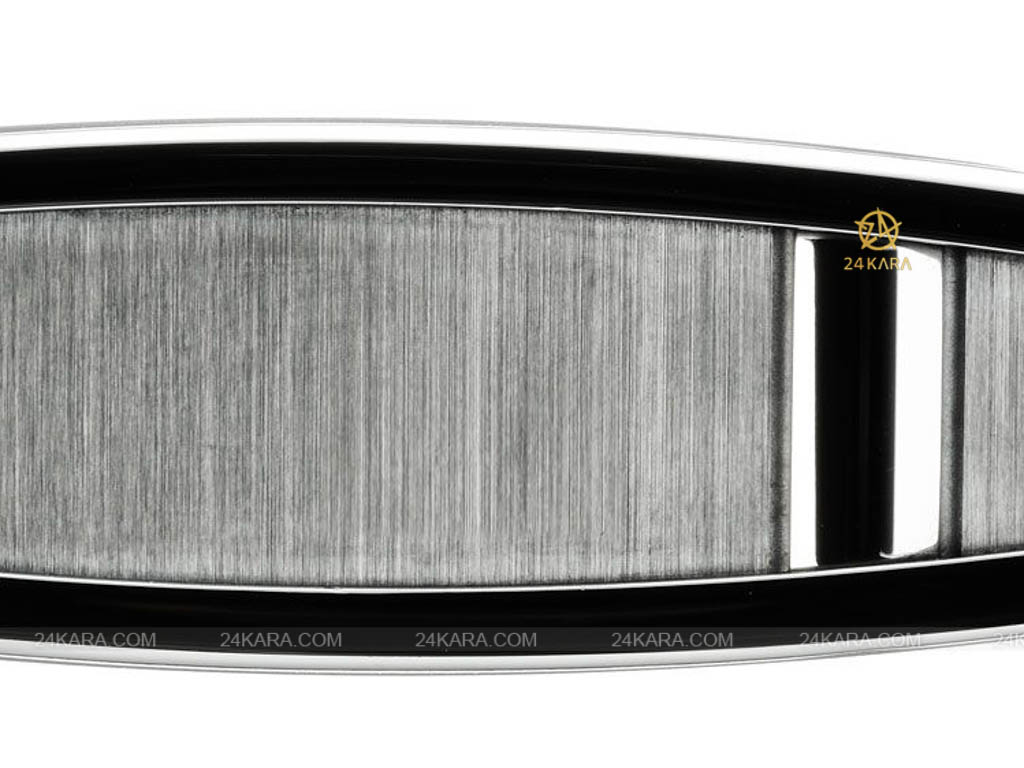

Taking advantage of the more generous dimensions of the RM 020 format to emphasise its architecture, we felt free to stretch and accentuate the curve and camber of the case. The rhomboid shape of the chain links is a clear reference to the Column of the Infinite by Brancusi, the brilliant 20th century sculptor. In the presence of this piece, we oscillate between the two utopias of absolute time and infinite space.’

Bezel là gì? 8 Tính Năng “Thú Vị” Trên Vòng Bezel Đồng Hồ

Đối với một chiếc đồng hồ, bên cạnh kiểu dáng và chất liệu thì vành bezel là bộ phận không thể thiếu. Vậy bạn có biết bezel là gì không? Hãy cùng 24Kara khám phá những điểm đặc sắc của vòng bezel và những tính năng thú vị mà nó mang lại trong bài viết này nhé!12 Mặt Số Đồng Hồ Rolex Khiến Dân Chơi Đồng Hồ Mê Mẩn

Mặt số là yếu tố quyết định vẻ đẹp và cá tính của mỗi chiếc đồng hồ, đặc biệt là với những mẫu đồng hồ Rolex. Trong bài viết này, 24 Kara sẽ cùng bạn khám phá những mặt số đồng hồ Rolex ấn tượng, giúp bạn làm phong phú thêm bộ sưu tập của mình.Review chi tiết đồng hồ Seiko Credor Signo GMT GCBZ997

Nhắc đến đồng hồ Nhật Bản, nhiều người thường nghĩ ngay đến Grand Seiko. Nhưng hơn thế nữa, có thể bạn chưa biết, Seiko luôn dành những sản phẩm cao cấp, tinh tuý nhất cho Nhật Bản như Credor hay Galante. Hôm nay, hãy cùng 24Kara khám phá một mẫu đồng hồ thuộc dòng Credor - chiếc Seiko Credor Signo GMT GCBZ997 để hiểu hơn về tinh hoa chế tác đồng hồ thủ công Nhật Bản nhé!

24KARA - Công ty Phân phối và Thẩm định Đồng hồ chính hãng

24Kara là một thương hiệu uy tín chuyên cung cấp dịch vụ thu mua và phân phối đồng hồ cao cấp chính hãng. Với sứ mệnh mang đến những sản phẩm đồng hồ đẳng cấp và chất lượng, 24Kara không chỉ phân phối các dòng đồng hồ nổi tiếng như Rolex, Hublot, Omega, Longines mà còn cam kết dịch vụ thu mua đồng hồ cũ với giá trị hợp lý, giúp khách hàng dễ dàng chuyển nhượng hoặc tìm kiếm những mẫu đồng hồ yêu thích. Đội ngũ chuyên gia của 24Kara luôn sẵn sàng tư vấn và thẩm định giá trị đồng hồ chính xác, mang đến cho khách hàng những trải nghiệm mua sắm an tâm và đáng tin cậy. Chúng tôi tự hào là địa chỉ đáng tin cậy cho những tín đồ đam mê đồng hồ cao cấp tại Hồ Chí Minh và Hà Nội.

SĐT: 0778 529 999

Email: sales@24kara.com

✪ Chi nhánh Hà Nội : 332 Bà Triệu, Phường Lê Đại Hành, Quận Hai Bà Trưng, Hà Nội.

✪ Chi nhánh Hồ Chí Minh: 132 Nguyễn Cư Trinh, Phường Nguyễn Cư Trinh, Quận 1, Hồ Chí Minh.

✪ Website: 24kara.com

✪ Instagram: www.instagram.com/24kara/

Copyright by Đồng Hồ 24Kara ® Since 2010

Góp ý & Khiếu nại: Sales@24kara.com

ID: 654572

Website nhằm mục đích giới thiệu thông tin đến cộng đồng người chơi đồng hồ, không nhằm mục đích kinh doanh

Công ty TNHH Thương Mại Dịch Vụ và Sản Xuất 24KARA

Địa chỉ: Số 8 ngách 91 ngõ Trại Cá, Trương Định, Hai Bà Trưng, Hà Nội